The Problem

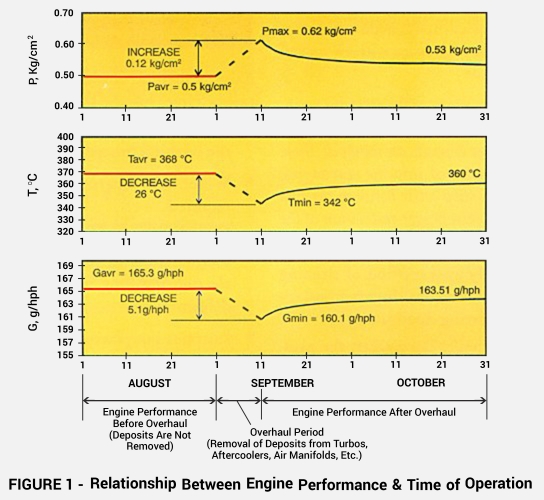

It is well known during the operation of supercharged engines, a gradual deterioration of performance occurs. One of the main causes is fouling

It is well known during the operation of supercharged engines, a gradual deterioration of performance occurs. One of the main causes is fouling

of the turbochargers and air coolers. The most intensive growth of the

deposit layer takes place during the first 50-200 hours of operation.

Deposits accumulated in the air coolers create the most significant problem, as they restrict the required air flow to the cylinders, resulting in

Poor combustion

Decrease of scavenging air pressure and volume of air suppled into cylinders

Increase of the exhaust gas temperatures

Higher thermal stresses on the engine

Increased fuel consumption

Existing Washing System Challenges

The washing system for the turbocharger (blower) is designed and supplied by the turbocharger manufacturer

The washing system for the air cooler is designed and supplied by the engine manufacturer

These two systems are contradictory. The washing system for the blower removes the deposits but transfers these deposits to the air cooler

The air cooler is not washed until there is an observed change in differential air pressure. During this window, the deposits have already built up on the fins and tubes of the air cooler